Current location:HOME > PRODUCT > Viscous aldehyde resin > Polyketone Resins(CF-105 & CF-120)

Polyketone Resins(CF-105 & CF-120)

General Description:

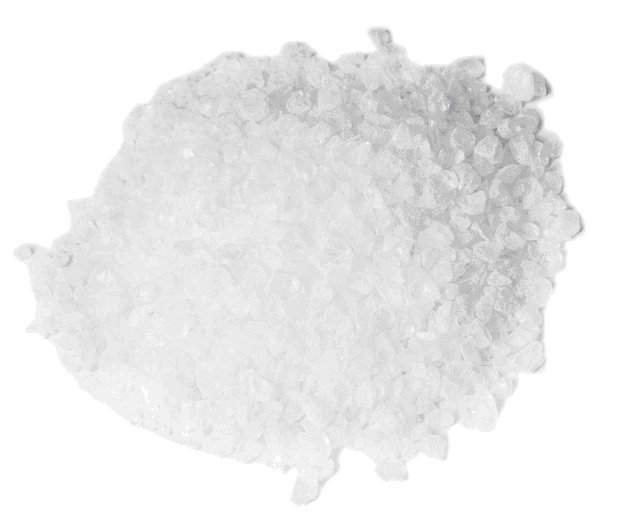

l CF series polyketone resin is aldehyde-ketone high molecular polymer, so it is called aldehyde-ketone resin.

l Light color, transparent, nontoxic, non-saponified hardened resin, and soluble in all the coating solvents except aliphatic hydrocarbon and water, with good compatibility with most resins and plasticizers.

l Considerably increase the glossiness, adhesive force, fullness, and aging resistance of the products.

Properties:

|

Test Items |

Unit |

CF-105 |

CF-120 |

Test Method |

|

Softening point |

℃ |

95~110 |

111~125 |

ISO 4625 |

|

Colourity |

Gardner color scale |

≤1 |

≤1 |

ISO 4630 |

|

Acidity value |

mgKOH/g |

≤1 |

≤1 |

ISO 3682 |

|

Hydroxyl value |

mgKOH/g |

100~120 |

80~100 |

ISO 4629 |

|

Density(20℃) |

g/cm3 |

1.15~1.17 |

1.15~1.17 |

DIN 53479 |

l The softening point range of CF polyketone resin is80℃~130℃.

l CF polyketone resins with high softening point usually has higher hardness, resistance to water, viscosity, resistance to after tack, dissolution and liberation velocity, heat resistance and resistance to grinding, and is mainly applied in paints and coatings.

l CF polyketone resin with low softening point usually has higher glossiness, solubility, hydroxyl value, pliability, waterproof dilution, compatibility, adhesive force, and flatting and anti-scaling feature, and is widely applied in ink products.

Applications:

l Paints:CF polyketone resins are applicable to the paints for plastic toys, nitro varnish, paints for chlorinated rubber, amino baking varnish, polyurethane paint, and varnish paint for paper. The recommended proportion is generally 5%~10% of solid content of the entire paint.

l Inks:CF polyketone resins are applicable to various ink systems, including compound ink, inks for surface printing, intaglio printing and letterpress printing, bronzing ink, Anti-counterfeiting ink, and the ink for ball pens. The typical proportion is 3%~15% added to the ink formula.

l Other applications:UV system, Nitro cellulose adhering agent, enclosure lighting oil for cigarette box, gloss oil for leather articles, cuticle cream and shoe polish.

Polyketone resins apply to UV coatings(engender“snowflake”), should pay attention to:

l First, do formula aging test in the UV system:If the UV specimen baked in an80℃oven over four hours, and then be put into gel, then the polyketone resin can't be used, and should be replaced;After eight hours without gel, the polyketone resin can be used.

l If polyketone resin is dissolved or dispersed in high temperature, the product maybe easy to gel. You should cool it and then make products.

![]()

![]()

![]()

Mr.

Zhang

Mr.

Zhang Mr.

Ren

Mr.

RenAddress:Room 1302,Building C6,Hengfeng Industrial City,Xixiang Sub-district Office,Bao’an District,Shenzhen,China

Telephone:0755-27695243,0755-27695809 Fax:0755-27695215 E-mail:szclef008@163.com